Sulfuric acid dilution coolers

Sulfuric acid dilution coolers are used in various industries to perform the dilution of 96 to 98.5% H2SO4 with water. It enables the safe dilution and cooling of H2SO4 to lower concentrations. GAB Neumann’s graphite sulfuric acid dilution coolers perform the dilution and the cooling of the acid in an integrated piece of equipment. The dilution takes place inside of the cooler. The mixing and therefore the dilution is progressively achieved as the fluids travel through the heat exchangers annular groove channels.

Snapshots

H2SO4 dilution cooler

GAB Neumann’s sulfuric acid coolers are very compact.

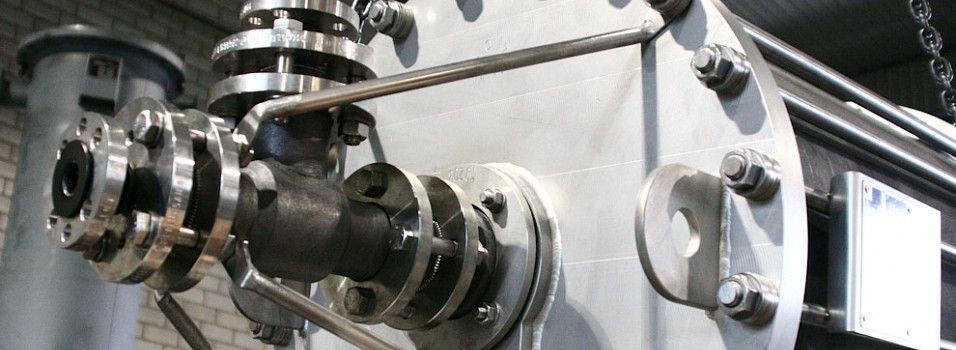

Sulfuric acid and water inlet of a sulfuric acid dilution cooler

In GAB Neumann’s sulfuric acid coolers the dilution takes place inside of the equipment.

H2SO4 dilution cooler

In GAB Neumann’s sulfuric acid coolers the dilution takes place inside of the equipment.

Two H2SO4 dilution coolers

Two sulfuric acid dilution coolers in operation in an automotive batteries manufacture.

3D Renderings

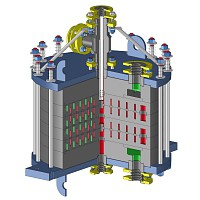

Details of a small annular groove sulfuric acid dilution cooler in graphite

For efficiency and safety reasons, in GAB Neumann’s sulfuric acid dilution coolers, the dilution takes place inside of the unit.

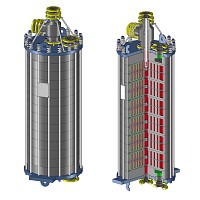

Large annular groove sulfuric acid dilution cooler in graphite

GAB Neumann’s sulfuric acid dilution coolers can be adapted to best meet expected flow and cooling requirements.

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

- Dilution T: PTFE

Design:

- Modular design: heat transfer surface, cross sections, and nozzle sizes can be adjusted to meet expected flow requirements

- Graphite discs with annular groove (spiral)

- Maximum disc diameter: 900 mm

- Graphite nozzles on product side

- Thermal expansion compensation ensured by tie rods and helical springs

- Carbon-fiber reinforcement (optional)

Key Features:

- Design pressure: -1 barg (full vacuum) to +10 barg (145 psig)

- Design temperature: -60 to +200°C (-76 to 392°F)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

Key Benefits:

- Mixing and cooling in one single unit

- Outstanding corrosion resistance

- Progressive mixing and cooling

- High operational safety

- No evaporation

- High efficiency

- No static mixer required

- Sturdy, compact, and modular design

- Gasket free design (fused discs)

- Resin free surfaces (impregnation before machining) ensures efficient heat transfer

- Self-cleaning design prevents fouling and clogging

- Highly reliable equipment therefore low cost of ownership and low maintenance cost

- Short lead time

- Long lifetime

Optional features:

- Carbon fiber reinforcement

Main applications:

- Mixing of concentrated H2SO4 with water and cooling of the diluted acid

Technical documentation

Sulfuric acid dilution coolers

Sulfuric acid dilution coolers are used in various industries to perform the dilution of 96 to 98.5% H2SO4 with water. It enables the safe dilution and cooling of H2SO4 to lower concentrations.

Sulfuric acid is produced from sulfur, oxygen and water. First sulfur is burned to produce sulfur dioxide (SO2). This is then oxidized to sulfur trioxide (SO3) using oxygen in the presence of a vanadium oxide catalyst. This reaction is reversible and the formation of the sulfur trioxide is exothermic. The sulfur trioxide is absorbed into 98.5% sulfuric acid (H2SO4) to form oleum (H2S2O7), also known as fuming sulfuric acid. The oleum is then diluted with water to form 98.5% concentrated sulfuric acid.

In order to produce sulfuric acid at lower concentrations, concentrated H2SO4 shall be diluted with water. This reaction is violent because the dilution process is highly exothermic thus causing the temperature of the diluted acid to rise sharply thus causing a risk of vaporization.

Concentrated H2SO4 is very viscous whereas water has a low viscosity therefore the mixing of concentrated sulfuric acid and water is neither immediate nor easy. It takes both time and efforts.

Hot concentrated H2SO4 is highly oxidizing and needs therefore to be diluted and cooled down rapidly.

GAB Neumann’s sulfuric acid dilution coolers

GAB Neumann’s graphite sulfuric acid dilution coolers perform the dilution and the cooling of the acid in an integrated piece of equipment. The dilution takes place inside of the cooler.

Thanks to the annular groove design of our coolers, the acid flow is turbulent. The mixing and therefore the dilution is progressively achieved as the fluids travel through the heat exchangers channels. This unique design prevents premature wear due to oxidation, avoids evaporation, and guaranties therefore a long lifetime to the equipment.

GAB Neumann’s unique annular groove dilution cooler design ensures high turbulence, effective mixing and highly efficient cooling of the diluted acid.

Industrial processes:

- Lead acid batteries

- Phosphoric acid

- and many more…

Associated products:

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com