Properties

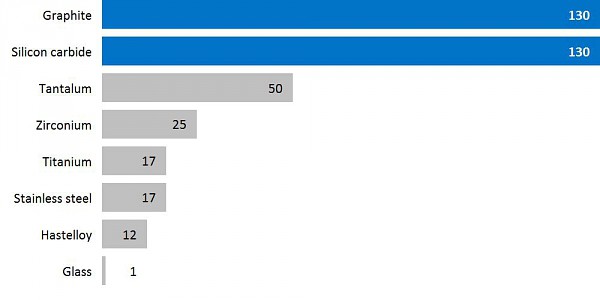

Thermal conductivity in international units (W/m.K)

With thermal conductivity of 130 W/m.K, silicon carbide outperforms most of the materials used for the construction of corrosion-resistant process equipment.

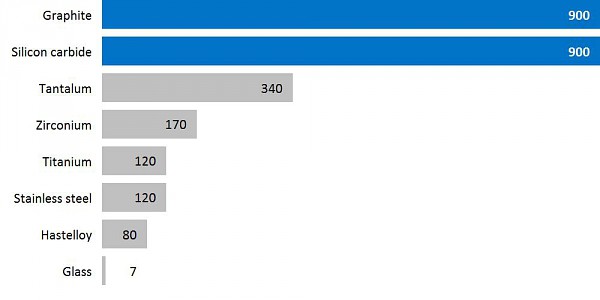

Thermal conductivity in imperial units (BTU.inch/hr.ft2.°F)

With thermal conductivity of 900 BTU.inch/hr.ft2.°F, silicon carbide outperforms most of the materials used for the construction of corrosion-resistant process equipment.

CORRESIC® Silicon carbide

GAB Neumann’s CORRESIC® product portfolio includes silicon carbide plates, block and tube, and shell and tube heat exchangers. Our individual plates, blocks, and tubes are all made of pressureless sintered silicon carbide. This manufacturing process confers its almost universal corrosion resistance to silicon carbide, its outstanding thermal conductivity, it hardness, and its mechanical strength.

Silicon carbide properties in international units

|

Materials |

Unit |

Plate |

Block |

Tubes |

|

Density (20°C) |

g/cm3 |

3.1 |

3.1 |

3.1 |

|

Flexural strength (4-Pkt. 20°C) |

MPa |

460 |

460 |

460 |

|

Compression strength (20°C) |

MPa |

2900 |

2900 |

2900 |

|

Elastic modulus (20°C) |

MPa |

410 |

410 |

410 |

|

Mohs Hardness |

|

9.6 |

9.6 |

9.6 |

|

Thermal expansion rate (20/200°C) |

10-6.K-1 |

2.9 |

2.9 |

2.9 |

|

Thermal conductivity (20/200°C) |

W/m.K |

130 |

130 |

130 |

|

Open porosity |

% |

0 |

0 |

0 |

|

Surface roughness Ra (after sintering) |

μm |

1.3 |

1.3 |

1.3 |

Silicon carbide properties in imperial units

|

Materials |

Unit |

Plate |

Block |

Tubes |

|

Density (68°F) |

oz/gal |

413.9 |

413.9 |

413.9 |

|

Flexural strength (4-Pkt. 68°F) |

ksi |

66.7 |

66.7 |

66.7 |

|

Compression strength (68°F) |

ksi |

420.6 |

420.6 |

420.6 |

|

Elastic modulus (68°F) |

msi |

59.5 |

59.5 |

59.5 |

|

Mohs Hardness |

|

9.6 |

9.6 |

9.6 |

|

Thermal expansion rate (68/392°F) |

10-6.°F-1 |

1.6 |

1.6 |

1.6 |

|

Thermal conductivity (68/392°F) |

BTU.inch/hr.ft2.°F |

901.3 |

901.3 |

901.3 |

|

Open porosity |

% |

0 |

0 |

0 |

|

Surface roughness Ra (after sintering) |

mils |

0.05 |

0.05 |

0.05 |

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com