Graphite columns and column internals

Graphite columns are designed for the distillation of ultra-corrosive fluids as well as the washing, absorption, or scrubbing of ultra-corrosive gases. Each graphite column is custom-made to best fit with existing process requirements. They consist in graphite cylindrical sections that are stacked one above the other.

Snapshots

Column section

Section of a graphite column.

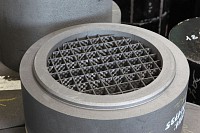

Graphite column with a CFC support grid

Support grid made of Carbon Fiber reinforced Composite (CFC). CFC support grids can have a very high opening rate. CFC is extremely light in weight, has high flexural strength and is corrosion resistant to even the strongest acids.

Liquid distributor

Liquid distributor above a packed section inside a fractionating column.

Side nozzle

Side nozzle of a carbon fiber reinforced graphite column section.

Column section with several side nozzles

Assembly of a graphite column section with several side nozzles.

Liquid distributor

Intermediate liquid distributor (view from above) in an graphite fractionating column.

Liquid distributor

Intermediate liquid distributor (view from below) in an graphite fractionating column.

Support grid

Support grid located right below a carbon Raschig rings section.

Column section with a gas injection nozzle

Column section with the main hydrochloric acid gas injection nozzle.

3D Renderings

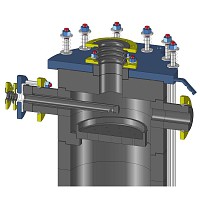

Graphite columns

GAB Neumann’s graphite columns are made of sections that are stacked one above the other

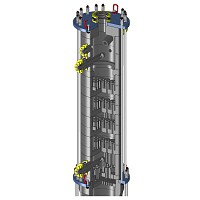

Sectional view of a graphite column

Sectional view of a graphite column with packing in the central area and bubble cap trays in the upper section.

Top section of a graphite column

Top section of a graphite column fitted with a horizontal plate that ensures the proper homogenous distribution of the liquid at the top of the structured packing section

Upper section of a graphite column

Upper section of a graphite column fitted with bubble cap trays. Tray towers are usually better at handling lower liquid rates.

Graphite bubble cap tray with overflow

Graphite is a very flexible material of construction for the manufacturing of all kinds of column internals

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Internals: impervious graphite or Carbon Fiber Reinforced Composite (CFC)

- Shell, Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

- PTFE and/or graphite gaskets between the column rings

Design:

- Modular design: diameter and number of sections can be adjusted

- Possible integration of process equipment (condenser, reboiler, etc...)

- Impregnated graphite discs with annular groove design (spiral)

- Column diameter: up to DN800 as a standard, larger diameters on request

- Full corrosion and vacuum resistance

- Graphite nozzles location and orientation as per process requirements

- Compensation of the differential thermal expansion with tie-rods and springs

- Thermal expansion compensation ensured by tie rods and helical springs

Key Features:

- Design pressure: -1 barg (full vacuum) to +3 barg (45 psig), depending on nominal diameter as well as design pressure and temperature

- Design temperature: -60 to +200°C (-76 to 392°F)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

- Internals: packing in graphite, ceramics, PTFE and other fluoropolymers, bubble cap trays and banana trays, support rings and support grids, liquid distributors, gas spargers, demisting beds, and custom-made parts on request

Key Benefits:

- Outstanding corrosion resistance on one side or on both sides

- Easy disassembly

- High operational safety

- Sturdy and modular design

- Short lead time

- Long lifetime

Technical documentation

Columns

Fractioning columns

Fractionating columns are used to distillate liquid mixtures in order to separate the mixture into its component parts, or fractions, based on the differences in volatilities. Fractionating columns are widely used in the chemical and fine chemical industries.

Distillation is an energy-intensive separation process. The effectiveness of the separation depends on the column height and diameter, the ratio of the column's height to diameter, and the separation trays or packing used. Distillation columns are usually operated at a continuous steady state. The amount of feed being added then equals the amount of product being removed. The amount of heat entering the column from the reboiler and with the feed must equal the amount heat removed by the overhead condenser and with the products. The heat entering a distillation column is a crucial operating parameter, addition of excess or insufficient heat to the column can lead to foaming, weeping, entrainment, or flooding. Fractionating columns have outlets at intervals up the column so that multiple products having different boiling ranges may be withdrawn from a column distilling a multi-component feed stream. The lightest therefore most volatile products with the lowest boiling points exit from the top of the columns and the "heaviest" products with the highest boiling points exit from the bottom. Fractionating columns use external reflux to achieve better separation of products.

Inside the column, the downflowing reflux liquid provides cooling and condensation of up-flowing vapors thereby increasing the efficacy of the distillation tower. The more reflux and/or more trays provided, the better is the tower's separation of lower boiling materials from higher boiling materials. The design and operation of a fractionating column depends on the composition of the feed and as well as the composition of the desired products. Simulation models are used both for design, operation, and construction.

Washing, absorption, or scrubbing columns

Washing, absorption, or scrubbing columns are air pollution control devices that can be used to remove some particulates and/or gases from industrial exhaust streams. They consist in columns with gas inlet at the bottom and washing liquid fed from the top over the entire cross-section. Gas and liquid are passed through the column at counter flow. Before the gas leaves at the top of the column, entrained scrubbing liquid drops are retained by adequate droplet separators. The column design (height, diameter, number of trays, packing sections heights, type of packing, etc…) depends on the cleaning task and the composition of the exhaust gas.

Mass transfer between gas and liquid

Packing material or bubble cap trays are used in the column to ensure an intimate contact between the up-flowing gases and the down-flowing liquids and therefore to generate the necessary mass transfer. Columns fitted with trays are usually better at handling solids or other sources of fouling. They operate also more efficiently at lower liquid rates. On the other hand, packed columns offer a lower pressure drop and are usually better at handling foaming systems.

Liquids tend to wet the surface of the packing, and the vapors pass across this wetted surface, where mass transfer takes place. Differently shaped packings have different surface areas and void space between packings. Both of these factors affect packing performance.

GAB Neumann’s graphite columns

GAB Neumann’s graphite columns are designed to distillate ultra-corrosive fluids and/or to wash, absorb, or scrub ultra-corrosive gases. Safety, reliability, and performance on the long-term are our primary considerations when we size, design and manufacture graphite columns.

Our graphite columns are custom made and therefore totally customizable. They are specifically adapted to the specific process requirements of ultra-corrosive applications. The diameters and the heights of the sections, the type, size and number of the trays, the type, size and number of the packing sections, the size, number, location and orientations of the nozzles can be adapted to best meet the process conditions, velocities, pressure drops, and mass transfer requirements. Any compatible packing material can be used. Graphite, PTFE and PVDF Raschig ring are commonly used.

They can be fitted with all kinds of optional features such as integrated condensers or reboilers, temperature and pressure sensors, carbon fiber reinforcement and sight glasses.

GAB Neumann's CFC column internal

In close collaboration with Nippon Kornmeyer Carbon Group (https://carbongroup.de/), GAB Neumann has developped a complete range of Carbon Fiber Reinforced Carbon (CFC) column internals. Support grids, holding grids, liquid distributors, liquid collectors, and many other type of column internals can made of CFC. CFC is a light weight, extremely strong material with an outstanding corrosion resistance to even the strongest acids. CFC support grids can be designed with a very high opening rate. It replaces advantageously support grids made of impervious graphite, glass, reactive metals, or glass lined steel.

Industrial processes:

- Hydrofluoric acid absorption

- Dry hydrochloric acid generation

- Hydrofluoric acid

- Fluorosilicic acid

- Halogenated organic solvents

- Treatment, purification and concentration of spent acids

- and more…

Optional features:

- In-line condenser, reboiler, or heat exchangers

- Temperature and pressure sensors

- Carbon fiber reinforcement

- Sight glass

Associated products:

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com