Graphite block heat exchangers

Graphite block heat exchangers are adapted to the heating, cooling, evaporation, condensation and absorption of highly corrosive liquid chemicals. This design is one of the most versatile type of impervious graphite heat exchangers. Rows of holes are drilled through graphite blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the impervious graphite left between the rows of holes which separate the mediums being used. Graphite block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

Snapshots

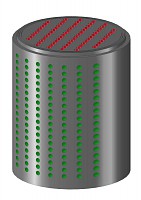

Details of a graphite block

Heat exchange blocks consist in solid graphite blocks that are drilled with rows of holes in horizontal and vertical directions

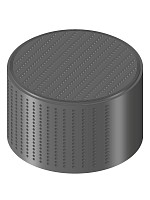

Different sizes of graphite blocks

In order to best fit with customers’ process requirements GAB Neumann has developed different types and sizes of graphite block heat exchangers

Graphite block heat exchanger equipped with a PTFE lined shell

If required the shell can be PTFE lined in order to allow heat transfer between two corrosive fluids

3D Renderings

GE21 Block

GAB Neumann offers graphite block heat exchangers of different sizes

GE21 Block

GAB Neumann offers graphite block heat exchangers of different sizes

GZ35 Block

GAB Neumann offers graphite block heat exchangers of different sizes

GE41 Block

GAB Neumann offers graphite block heat exchangers of different sizes

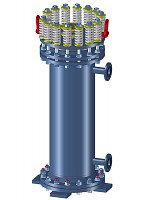

Vertical GE35 graphite block heat exchanger

Graphite block heat exchangers consist in a stack of graphite blocks encapsulated in a steel shell. The blocks are drilled in perpendicular directions. The heat transfer takes place in the graphite walls between the holes.

Horizontal GZ21 graphite block heat exchanger

GAB Neumann’s graphite heat exchangers can be installed either vertically, horizontally, or with a slope.

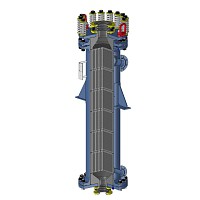

Vertical GE41 graphite block heat exchanger with custom made expansion system and a demountable header.

A heat exchanger can be adapted to specific process requirements, here with a removable header for easy cleaning of the process side and a custom made expansion system.

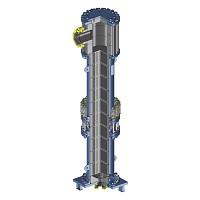

Vertical block heat exchanger of the GE/GZ series

Graphite block heat exchangers consist in a stack of graphite blocks encapsulated in a steel shell.

3D Animations

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Shell, Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

- PTFE gaskets between the blocks

Design:

- Totally modular design: number of blocks, size of blocks and number of passes can be adjusted

- Different drilling diameters on process and service sides

- Maximum block diameter: 900 mm

- Graphite nozzles on product side

- Thermal expansion compensation ensured by tie rods and helical springs

Key Features:

- Design pressure: -1 barg (full vacuum) to +10 barg (145 psig)

- Design temperature: -60 to +200°C (-76 to 392°F)

- Heat transfer area: up to 163 m2 (1755 ft2)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

Key Benefits:

- Outstanding corrosion resistance on one side or on both sides

- Good heat transfer performance thanks to adjustable cross sections on both sides

- Large transfer areas and comparatively low pressure drop on the product side

- Easy disassembly and ability to mechanically clean each block

- Impregnation before machining ensures resin free surfaces

- Single or double-row drillings on product side

- High operational safety

- Sturdy and modular design

- Short lead time

- Long lifetime

Optional features:

- Removable headers for easy mechanical cleaning

- Rubber lined, glass lined or PTFE lined shell for corrosive fluids on shell side

- Very large drilling diameter to allow crystallization and prevent clogging

- Protection against abrasion

- Sight glass

Main applications:

- Cooling, condensation, heating, evaporation and absorption of ultra-corrosive chemicals

- Heat transfer between two ultra-corrosive chemicals

- Best suited for single purpose units

Technical documentation

Block heat exchangers

A block heat exchanger is a process device which transfers heat from one medium to another without direct contact between fluids. For material properties, cost and efficiency reasons block heat exchangers only exist in impervious graphite and silicon carbide. Rows of holes are drilled through the blocks both horizontally and vertically to form the process and service channels. Heat is transferred by conduction through the exchanger material left between the rows of holes which separate the mediums being used. Impervious graphite blocks can be cubic or cylindrical. Silicon carbide blocks are cylindrical. Graphite block heat exchangers consist in a stack of blocks encapsulated in a steel shell.

The thermal performance of block heat exchangers can vary significantly. It is therefore essential to select the type and size of block heat exchanger that is the most adapted to the specific application and industrial process. There are a number of considerations including flow rate, pressure drop, risk of erosion, design pressure and temperature, materials compatibility, fouling, and many more that should be taken in account.

GAB Neumann’s impervious graphite block heat exchangers - GE/GZ series

GAB Neumann’s impervious graphite block heat exchangers are designed to cool down, condense, heat up, evaporate, sublime, crystallize, or absorb ultra-corrosive chemicals. Safety, reliability, availability, and performance on the long-term are our primary considerations when we size, design and manufacture block heat exchangers.

Our extended and highly customizable block heat exchanger portfolio enables us to provide particularly adapted solutions to ultra-corrosive heat transfers. All our cylindrical block heat exchangers’ designs are totally modular to best fit with individual process specification. The number and size of blocks, the number and diameters of holes as well as the number of passes both on process and service sides can be adapted to best meet the velocities, pressure drops, and heat transfer requirements.

They can be fitted with all kinds of optional features such as sight glasses or demountable headers to better fit the process requirements.

All our impervious graphite block heat exchangers are machined after phenolic resin impregnation thus guarantying a heat transfer surface totally free of resin and ensuring therefore the highest possible heat transfer rate.

Industrial processes:

- Phosphoric acid

- Crop protection

- Fumed silica

- Silicones

- Titanium dioxide

- Fine chemicals

- Active pharmaceutical ingredients

- Carbon steel and stainless-steel pickling

- Copper electrolysis

- Epichlorohydrin

- Vinyl chloride monomer

- Fire retardants

- Flavors and fragrances

- Vitamins

- Isocyanates

- Viscose

- Polycarbonate

- Coagulants

- Treatment, purification and concentration of spent acids

- Sulfuric acid dilution

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com