Manufacturing Process

Impervious graphite for process equipment applications is manufactured in two main steps. First synthetic graphite is manufactured. Then this material is impregnated with phenolic resin to make it impervious and enhance its mechanical characteristics.

GAB Neumann exclusively uses graphite from western sources (United States of America, Europe or Japanese suppliers only). Our process uses a homogenous, fine-grain graphite with a compact grain structure, an optimal grain and pore size distribution, rendering it exempt from structural irregularities such as cracks, large pores, or impurities.

In close collaboration with a renowned European resin manufacturer, GAB Neumann has developed a phenolic resin that is optimized for the type of graphite it uses and for its manufacturing process.

Snapshots

Raw graphite

GAB Neumann uses a homogenous fine grain graphite with a compact grain structure, an optimal grain and pore sizes distribution and exempt from structural irregularities such as cracks, large pores, or impurities.

Impregnated graphite material

Piece of graphite material after phenolic resin impregnation. The excess of resin at the surface of the block will be removed later on.

Machining of a graphite part

Phenolic resin impregnated graphite is easy to machine (sawing, milling, drilling, or turning). CNC or conventional machines may be used.

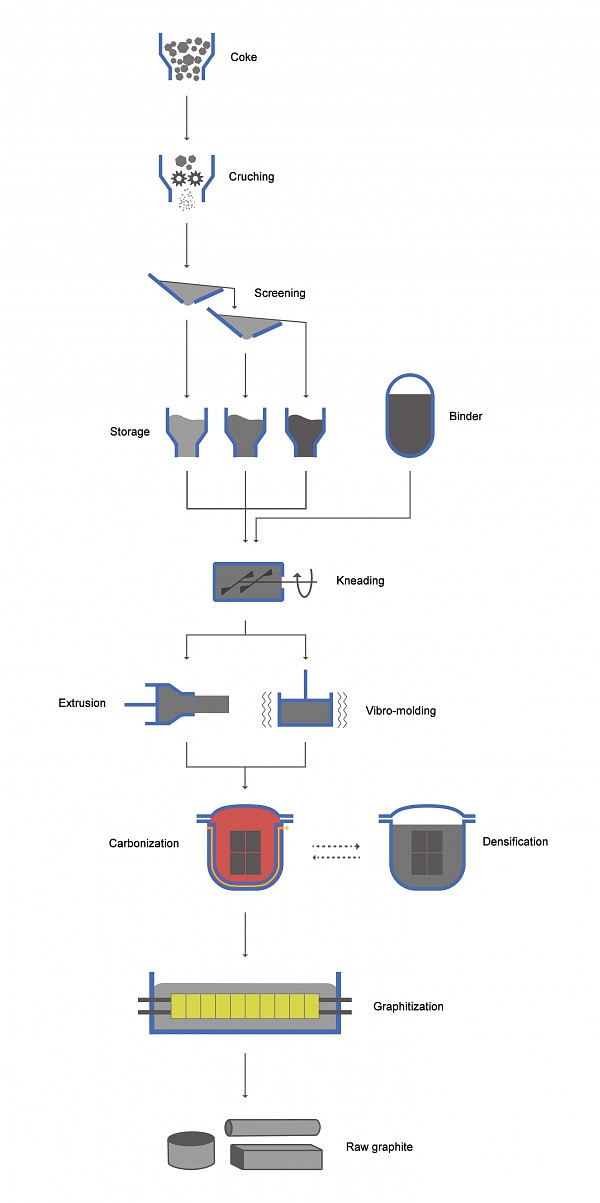

Synthetic graphite manufacturing process

The synthetic graphite manufacturing process includes numerous steps namely powder preparation, shape forming, baking, pitch impregnation or densification, rebaking, and graphitization.

1. Powder and paste preparation

Raw materials for synthetic graphite fabrication (petroleum coke, pitch coke, carbon black, natural graphite and secondary graphite scrap are loaded and stored in raw material silos. First, the raw materials are ground in crushers and ball mills. The resulting powder is then conditioned according to the particle size distribution. Finally, the powder is blended with a binder to produce a paste. Coal tar pitch or petroleum pitch are used as binders.

2. Shape forming

The resulting pasty mixture may be compacted using one of the shape forming techniques: extrusion, vibro-molding or cold isostatic pressing.

- Extrusion consists in forcing the pasty mixture through a die with an opening. Extrusion results in a long product such as rods, bars, long plates, or tubes with regular cross-sections, which may be cut into pieces of the required length. Extruded graphite materials are isotropic. The properties in the extrusion direction differ from the properties in other directions.

- Vibration molding is a discontinuous shaping method for products with large dimensions. A mold is filled with the pasty mixture and a heavy metal plate is put on top of it. Then the material is compacted by vibrating the mold. The formed bodies show a higher degree of isotropy compared to extruded materials.

- Cold isostatic pressing is the powder compaction method conducted at room temperature and involving applying pressure from multiple directions through a liquid medium surrounding the compacted part. A flexible mold immersed in a pressurized liquid medium is used. Materials with uniform anisotropic structure are prepared using the isostatic pressing method.

3. Baking

The compacted parts are heat treated in an anaerobic baking furnace at temperatures between 900 and 1200°C (1650 and 2200°F). Carbonization occurs during baking. It results in the thermal decomposition of the binder into elemental carbon and volatile components. Carbon formed in the carbonization process binds the powder particles. The volume of the binder is higher than the volume of the formed carbon. Therefore, carbonization results in the formation of pores. The total relative volume of porosity is determined by the binder quantity.

4. Pitch impregnation

At this point in the process the carbon parts may be impregnated with pitch and re-baked to reduce its porosity. Impregnation is typically performed using a pitch lower in viscosity than the original binder pitch. Low viscosity is required in order to fill gaps more completely. Petroleum pitch is normally utilized for this function.

For some high-density graphite grades, the carbon parts may go through the baking, pitch impregnation, rebaking cycle several times. Our GPX 1 graphite is manufactured using a raw graphite material that has been densified with pitch and rebaked. Our GPX 2 graphite is manufactured using a raw graphite material that has been densified with pitch, rebaked, re-densified with pitch and rebaked again.

5. Graphitization

At this stage the shaped, baked, pitch impregnated, and rebaked parts are heat treated in an anaerobic environment at an extremely high temperature of 2700 to 3000°C (4900 to 5450°F).

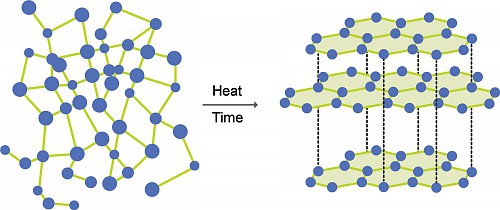

Graphitization results in the crystallization of amorphous precursor carbon, which transforms into crystalline graphite. Under the influence of temperature, the crystallites grow and rearrange in an ordered pattern of stacked parallel planes. This transformation is accompanied by a change in the physical properties of the material. During this high temperature treatment graphite is also purified since most of its impurities (binder residues, gases, oxides, sulfur) vaporize.

Graphitization is performed in an Acheson-type furnace. This furnace consists of a central chamber surrounded by external walls made of some refractory material such as firebrick. The chamber is roughly rectangular in outline. The top is open. The Acheson furnace is nothing more than a room without a ceiling, designed to keep in the heat generated by electrical resistance heating of the carbon charge.

The end walls of the Acheson furnace are fitted with graphite buss bars. These buss bars extend to the outside wall of the furnace, where they are coupled with large, water-cooled, caliper copper buss bars.

To load an empty furnace, baked carbon blanks are placed in a pre-determined configuration. Carbon articles may be loaded parallel or perpendicular to the power supply buss bars located on the furnace end walls.

Since graphitization process temperatures are expected to reach 2800°C (5070°F) or more it is of utmost importance that oxygen be excluded from the furnace. This is accomplished by covering the carbon articles with some oxygen scavenging material.

Once the articles to be graphitized are placed in the Acheson furnace and covered with the appropriate packing material, a direct current of low voltage and very high amperage is applied to the furnace charge. The furnace load heats up due to its own electrical resistance. As heating progresses, furnace resistance drops due to the increase in conductivity, resulting from the formation of graphitic carbon at the expense of amorphous carbon.

Furnace conditions are constantly monitored, along with power consumption. When the operator determines that the proper furnace temperature has been reached, or that the charge is fully graphitized, the furnace's power supply is cut. The furnace is allowed to cool and the graphitized articles are removed.

Carbon & graphite structures

With heat and time the amorphous carbon structure (left) turns into the crystalline graphite structure (right).

Amorphous carbon is hard and very difficult to machine. It has low electrical and thermal conductivities.

On the contrary, graphite is crystalline. It is easy to machine. It has very high electrical and thermal conductivities.

6. Quality checks

The graphitized articles go through a series of tests and inspections before being shipped. At this stage, the resulting graphite material already has excellent corrosion resistance and outstanding thermal conductivity. However, it is highly porous and therefore not at all impervious.

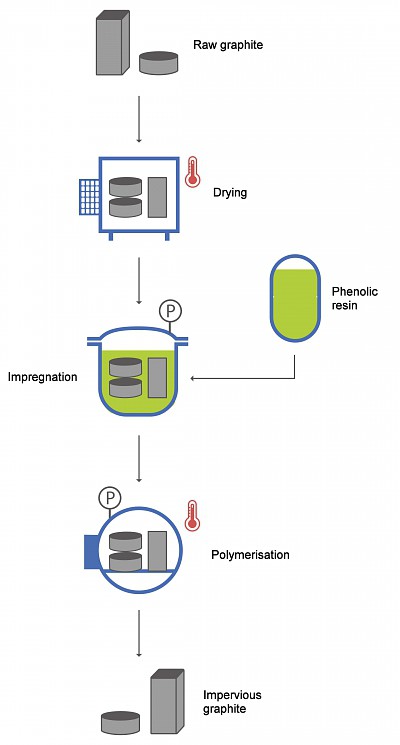

Phenolic resin impregnation

For process equipment applications, synthetic graphite should be made totally impervious. This is achieved by impregnating it with resin. Phenolic resin has been selected because of its superior corrosion resistance and mechanical strength.

GAB Neumann has developed, in close collaboration with a renowned European resin manufacturer, a phenolic resin that is optimized for the type of graphite it uses and for its manufacturing process.

The phenolic resin impregnation process includes the three steps namely drying of the graphite material, its impregnation with phenolic resin, and finally its curing.

1. Drying

Raw graphite bars are placed in a drying chambers, at a temperature of about 110°C (230°F), for as long as it takes them to release all of their moisture.

2. Phenolic resin impregnation

The dry graphite bars are then put into large autoclaves. The autoclaves are sealed, and then a deep vacuum is applied in order to remove the remaining traces of moisture from the material and to remove any air from inside of the material’s pores.

Then phenolic resin is introduced into the autoclave through the bottom valve. The liquid level should be raised substantially above all the graphite blocks since the level will decrease once the resin penetrates into the blocks. High-pressure is applied to force the resin to penetrate to the very core of the graphite bars.

Once impregnation is complete, after several days, the excess of resin is transferred back to the resin tank and the pressure is released. GAB Neumann thoroughly impregnates its graphite parts to their core in one single step.

3. Polymerization

The resin-impregnated graphite bars are then transferred to another autoclave. The parts are progressively heated until the polymerization temperature of the phenolic resin is reached. At 160°C (320°F) polycondensation (water elimination) occurs, and ether groups are formed. At about 180°C (356°F) another polycondensation occurs resulting in the formation of methylene groups. A three-dimensional, cross-linked, solid, and durable polymer is created.

After polymerization, tiny and well-dispersed steam bubbles are encapsulated in the resin. All pores are totally filled with phenolic resin, and there are no gaps (perfect wetting) between the resin and the graphite walls. The resulting materials, GAB Neumann’s GPX 1 and GPX 2, have outstanding chemical resistance to most common chemicals, especially acids, and high, long-term mechanical strength and stability.

4. Quality checks

The phenolic resin impregnated graphite pieces go through a series of tests and inspections before the machining and manufacturing of process equipment parts.

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com