Graphite multi-stage steam jet vacuum pumps

Graphite multi-stage steam jet vacuum pumps are used in various industries to remove gas molecules from a volume in order to leave behind a partial vacuum. They are a reliable alternative to vacuum pumps. GAB Neumann offer graphite single and multi-stages steam jet vacuum pumps for ultra-corrosive applications. They consist in several graphite steam ejectors and graphite condensers in series.

Snapshots

Graphite steam jet ejector

Graphite team jet ejector for the generation of vacuum in ultra-corrosive applications

Two graphite steam jet ejectors connected to a graphite condenser

Two steam jet ejectors connected to two separate sections of a graphite condenser

Three stages steam jet vacuum pump

Instead of having one condenser between each steam jet vacuum pump it is possible to partition the heat transfer surface of a large condenser in several independent condensation areas

3D Renderings

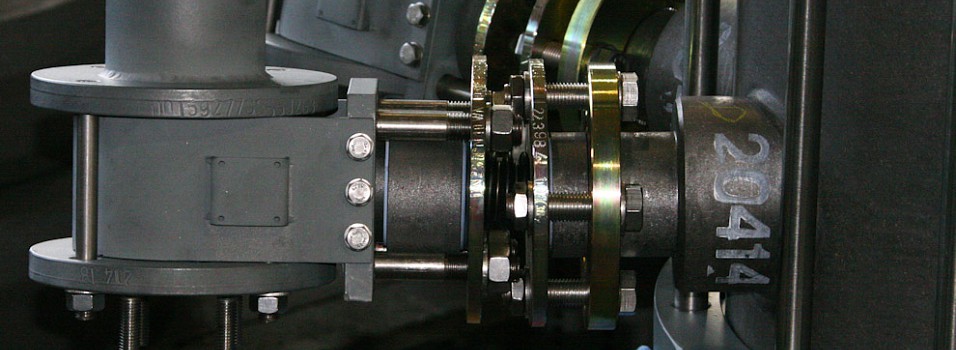

Steam jet nozzle

GAB Neumann’s graphite steam jets are designed to minimize erosion and maximize performance.

Steam jet ejector

GAB Neumann’s graphite steam jet ejectors.

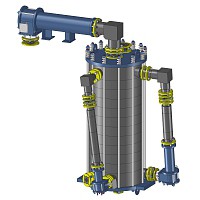

3 stages vacuum group with a single heat exchanger split into 3 condensers

Instead of having one condenser between each steam jet vacuum pump it is possible to partition the heat transfer surface of a large condenser in several independent condensation areas

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

Design:

- Modular design: number and sizes of steam ejectors as well as the number, cross section and heat transfer surfaces of intermediate condensers can be adapted to meet process requirements such as vacuum level, flow rate and steam consumption

- Graphite nozzles on product and on service sides

- Thermal expansion compensation ensured by tie rods and helical springs

- Carbon-fiber reinforcement (optional)

Key Features:

- Deep vacuum (< 1 mbar) possible

- Design pressure: -1 barg (full vacuum) to +10 barg (145 psig)

- Design temperature: -60 to +200°C (-76 to 392°F)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

Key Benefits:

- Steady, reliable, and cost-effective vacuum generation

- Outstanding corrosion resistance

- High operational reliability (no moving part)

- Sturdy, compact, and modular design

- Gasket free design (fused discs)

- Resin free surfaces (impregnation before machining) ensures efficient heat transfer

- Highly reliable equipment therefore low cost of ownership and low maintenance cost

- Short lead time

- Long lifetime

Optional features:

- Carbon fiber reinforcement

Main applications:

- Vacuum generation for chemical, pharmaceutical or fine chemical applications

Technical documentation

Multi-stage steam jet vacuum pumps

Multi-stage steam jet vacuum pumps are used in various industries to remove gas molecules from a volume in order to leave behind a partial vacuum. They are a reliable alternative to vacuum pumps.

Steam jet ejectors

Steam jet ejectors offer a simple, reliable, low-cost way to produce vacuum. They are especially effective in the chemical industry where an on-site supply of the high-pressure motive gas is available.

Steam jet ejectors are considered an alternative to mechanical vacuum pumps because no source of power is required other than the motive gas, they have no moving parts, they are reliable, easy to install, to operate and to maintain.

The operating principle of an ejector is to convert pressure into speed. This occurs by an adiabatic expansion of motive steam through a convergent-divergent nozzle from the motive pressure to suction pressure. The result is a supersonic speed out of the nozzle. The motive steam expands up to a pressure below the suction pressure. This creates a depression that enters the suction load into the ejector. Motive steam at high speed is mixed with the suction flow and enters the convergent-divergent diffuser. The speed is then transformed into pressure. The convergent section of the diffuser reduces the speed, pressure shock occurs in the throat of the diffuser and divergent diffuser section increases the cross-sectional area to the flow and speed are turning into pressure energy.

Multi-stage steam jet vacuum pumps

Single stage steam jet vacuum pumps feature a compression ratio between 1:7 and 1:10. Therefore, for low suction pressures, jet vacuum pumps shall be combined in series. Between two jet pumps the motive steam is condensed as far as possible in order to reduce the energy requirement of the next stage.

If the condensation temperature is too low at the intermediate temperature, several ejectors might be installed in series without condensers in between. Multi-stage steam jet vacuum pumps can be designed for suction pressures down to 1 mbar or lower. The maximum compression ratio for a steam jet vacuum pump depends on the suction pressure and the pressure of the available motive steam. For steam jet pumps for suction pressure of less than 6 mbar the head and the mixing nozzle shall be heated to prevent the formation of ice.

Graphite steam jet ejectors

In highly corrosive environments graphite steam jet ejectors offer a low-cost alternative to very costly and maintenance intensive corrosion resistant mechanical vacuum pumps.

Multi-stage steam jet corrosion-resistant vacuum pumps

In corrosion-resistant vacuum pumps graphite steam ejectors and well as graphite condensers are used.

GAB Neumann’s steam ejectors

Our graphite steam jets are designed to minimize erosion and maximize performance. They are the key component of our graphite steam ejectors.

GAB Neumann’s graphite multi-stage steam jet vacuum pumps

GAB Neumann designs and manufactures graphite single and multi-stage steam jet vacuum pumps for ultra-corrosive applications. They consist in several steam ejectors and condensers in series. It is possible to reach a vacuum level of 150 mbar and less with a single steam ejector and a condenser. With 2 ejectors and condensers a vacuum level of 20 mbar and less can be reach, 3 mbar or less with three, 1 mbar or less with four and 0.2 mbar or less with 5 in series.

Instead of having one condenser between each steam jet vacuum pump it is also possible to split the heat transfer surface of a larger condenser in several independent condensation areas. This technique allows major savings since it necessitates significantly less piping and a lower number of condenser(s). The resulting units are therefore compacter and cheaper.

Industrial processes:

- Phosphoric acid

- Crop protection

- Fine chemicals

- Active pharmaceutical ingredients

- Fire retardants

- Flavors and fragrances

- Vitamins

- and many more…

Associated products

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com