Custom-made graphite heat exchangers

GAB Neumann’s has an extended experience in the sizing, design and manufacturing of graphite heat exchanger. Over the last 50 some years we have designed, adapted and/or customized our products to best meet with the highly specific and sometimes unique requirements (multiple stages condensation, crystallization, continuous reactor, reverse sublimation, etc…) of our customers.

Snapshots

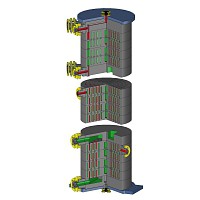

Custom-designed crystallizer

The graphite section of a crystallizer is designed to enable crystallization while preventing clogging. The very large slots enable the crystallization without any clogging risk.

Distribution section of a falling film evaporator

GAB Neumann's falling film evaporators have a unique design that ensures their higher efficiency.

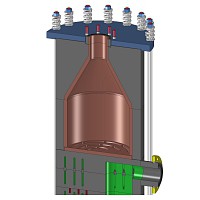

Top section of a falling film evaporator

GAB Neumann's falling film evaporators have a unique design that ensures their higher efficiency.

3D Renderings

G1 graphite heat exchanger

Our G1 graphite heat exchanger sections can be used as in-line reflux condensers at the top of distillation a column

CPX amorphous carbon lined graphite heat exchanger

Our CPX amorphous carbon material may be used to protect graphite heat exchangers from erosion

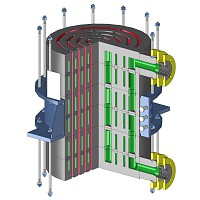

Different sections of a graphite continuous reactor

Different service side heating or cooling media can be used in different sections of a custom-made graphite heat exchanger. On process side media can be added or extracted to meet process requirements. It is therefore possible a continuous reactor that is exactly meets the process requirements.

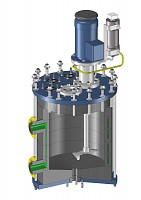

Agitated reactor

Agitated reactor in graphite with a water cooled jacket.

Materials:

- Impervious graphite: GAB GPX1, GPX1T or GPX2

- Impervious amorphous carbon to prevent erosion

- PTFE lined steel, glass lined steel, glass, fiber reinforced plastic, reactive metals, and/or fluoropolymers parts if required

- Shell, Pressure plates and flanges: carbon steel or stainless steel

- Tie rods, nuts, bolts, washers, springs: stainless steel

- PTFE gaskets between the blocks

Design:

- Association of different designs and materials of construction

- Association of different cooling or heating media in the same piece of equipment

- Custom and modular design to meet process requirements

- Diameters, widths, depths and heights adapted to the process requirements on process and on service sides

- Thermal expansion compensation adapted to the specific requirement

Key Features:

- Design parameters perfectly adapted to the process requirements

- Design pressure: -1 barg (full vacuum) to +16 barg (230 psig)

- Design temperature: -60 to +200°C (-76 to 392°F)

- Heat transfer area: up to 100 m2 (up to 1076 ft2)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

Key Benefits:

- Design perfectly adapted to the specific process requirements

- Outstanding corrosion resistance against acid, bases and oxidizing media

- Optimized heat transfer performance

- Self-cleaning design

- High operational safety

- Long lifetime

Optional features:

- Removable headers for easy mechanical cleaning

- Sight glass

Main applications:

- Complex, unique, sensitive, and usually one-of-a-kind thermal processes

- Cooling, condensation, heating, evaporation and absorption of ultra-corrosive and/or oxidizing chemicals or ultra-pure chemicals.

- Processes involving or potentially involving crystallization or reverse sublimation

- Suited for single purpose units

Technical documentation

Custom-made heat exchangers

A heat exchanger is a process device which transfers heat from one medium to another without direct contact between fluids. For material properties, cost and efficiency reasons we design custom-made heat exchangers exclusively in impervious graphite and silicon carbide. Heat is transferred by conduction through the exchanger material left between the channels or rows of holes which separate the media being used.

Our standard pieces of process equipment are totally modular. It is therefore possible to combine and customize bits and pieces from one series of process equipment with other series to form custom-made pieces of equipment that are ultimately perfectly adapted to unique process requirements. Our custom-made heat exchangers can combine the heating, cooling, evaporation, condensation and absorption of highly corrosive chemicals.

The thermal performance of heat exchangers can vary significantly. It is therefore essential to select the type and size of heat exchanger that is the most adapted to the specific application and industrial process. There are a number of considerations including flow rate, pressure drop, risk of erosion, design pressure and temperature, materials compatibility, fooling, and many more that should be taken in account.

GAB Neumann’s custom-made graphite heat exchangers

GAB Neumann’s custom-made graphite heat exchangers are designed to meet specific process requirements. They are designed to cool down, condense, heat up, evaporate, sublime, crystallize, absorb, separate, and/or mix ultra-corrosive chemicals. Safety, reliability, availability, and performance on the long-term are always our primary considerations when we size, design and manufacture custom-made graphite heat exchangers.

Our extended, modular, and highly customizable graphite heat exchanger portfolio enables us to design specific solutions to ultra-corrosive heat transfers. All the parameters (size, diameters, channel widths and depths, height, cross sections, heat transfer surfaces, as well as the number of passes both on process and service sides) can be adapted to best meet the velocities, pressure drops, and heat transfer requirements.

They can be fitted with all kinds of optional features such as sight glasses, additional nozzles, sensors, or demountable headers to better fit the process requirements.

Industrial processes:

- Phosphoric acid

- Crop protection

- Fumed silica

- Silicones

- Titanium dioxide

- Fine chemicals

- Active pharmaceutical ingredients

- Carbon steel and stainless-steel pickling

- Copper electrolysis

- Epichlorohydrin

- Vinyl chloride monomer

- Fire retardants

- Flavors and fragrances

- Vitamins

- Isocyanates

- Viscose

- Polycarbonate

- Coagulants

- Treatment, purification and concentration of spent acids

- Sulfuric acid dilution

- and many more…

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com