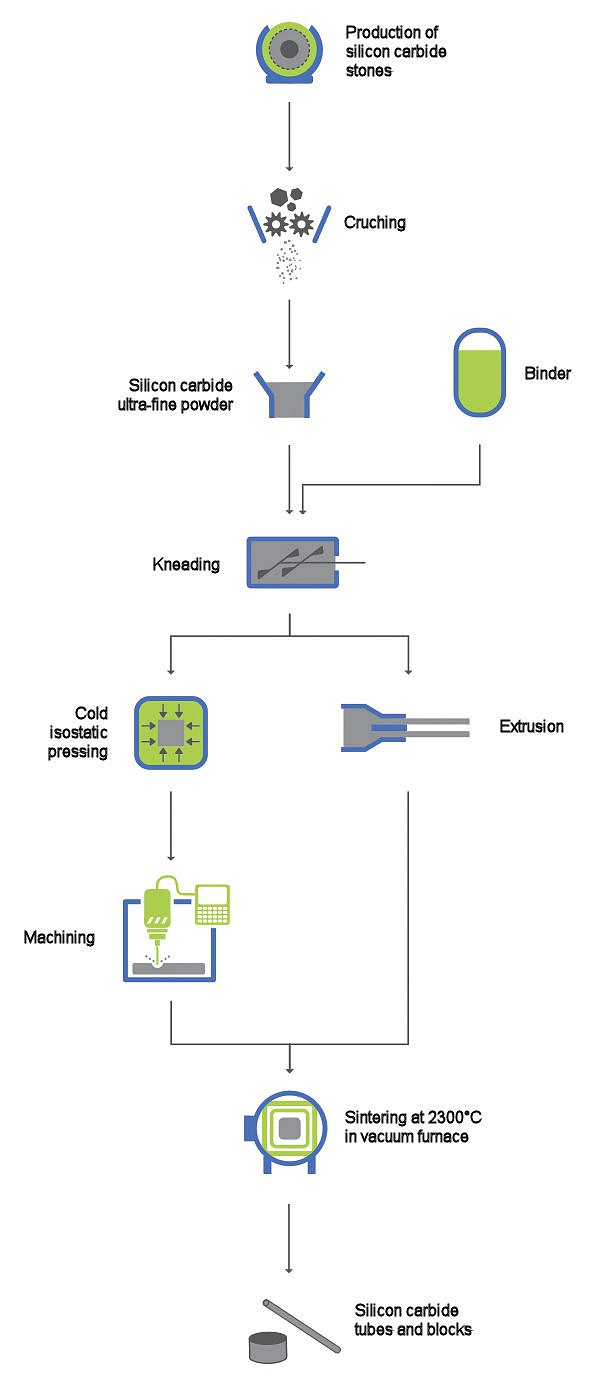

Manufacturing process

Silicon carbide for process equipment applications is manufactured by the sintering process. First the silicon carbide parts are shaped by extrusion (tubes) or cold isostatic pressing (plates and blocks). Then they are machined (plates and blocks). Finally, they are sintered under vacuum at a very high temperature. This demanding process confers its ultimate corrosion resistance, its extreme hardness, and its mechanical properties to our CORROSIC® material. GAB Neumann only uses pressureless-sintered silicon carbide monolithic parts from Western sources (United States of America or Europe).

Manufacturing process of silicon carbide plates, blocks, and tubes

The silicon carbide manufacturing process includes numerous steps namely, powder preparation, mixing with the binder, shape forming, machining, sintering, and eventually lapping or grinding.

1. Powder preparation

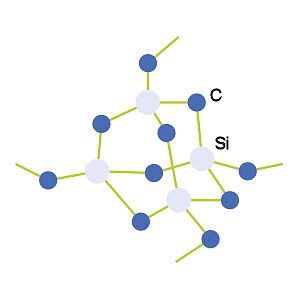

Silicon carbide (SiC) is a compound of silicon and carbon with a chemical formula of SiC. The simplest manufacturing process for producing silicon carbide is to combine silica sand and carbon in an Acheson graphite electric resistance furnace at a high temperature, between 1600°C (2910°F) and 2500°C (4530°F). Fine silicon particles can be converted to silicon carbide (SiC) by heating in the excess carbon from the organic material. The silica fume, which is a byproduct of producing silicon metal and ferrosilicon alloys, also can be converted to SiC by heating it with graphite at 1500°C (2730°F). The material formed in the Acheson furnace varies in purity. The silicon carbide “stones” and grains are turned into a fine powder by crushing, and then purified with halogens.

2. Kneading

The fine grain (sub-micron) powder is then homogeneously mixed with non-oxide sintering aids (a binder) to form a paste. Different binders including organosilicon binders may be used.

3. Shape forming

The resulting pasty mixture may be compacted and shaped either by extrusion or by cold isostatic pressing.

- Extrusion consists in forcing the pasty mixture through a die with an opening. Silicon carbide tubes are produced through extrusion. The properties in the extrusion direction differ from the properties in other directions.

- Cold isostatic pressing is the powder compaction method conducted at room temperature, and it involves applying pressure from multiple directions through a liquid medium surrounding the compacted part. A flexible mold immersed in a pressurized liquid medium is used. Materials with a uniform anisotropic structure are prepared using an isostatic pressing method. The materials used to produce silicon carbide plates and blocks are manufactured by cold isostatic pressing.

4. Computer Numerical Control (CNC) Machining

CNC machining is used to machine the surface of the plates or drill the holes on process and services sides in the cylindrical blocks. Due to the very low mechanical strength of the green material, special care is required here. With the help of unique fixture, the components are turned, milled, and drilled according to specific machining parameters.

5. Sintering

Following the forming stage, the material is sintered in an inert atmosphere at temperatures up to 2300°C (4170°F). During the sintering process, and more precisely between approximately 1900°C (3450°F) and 2150°C (3900°F), the products shrink isostatically by a factor of roughly 20%. The block height, diameter and hole diameters all shrink by roughly 20%. The tube diameter, wall thickness and length also shrink.

Silicon carbide structure

Silicon carbide is the second hardest material on earth and is nearly impossible to machine. It has very high thermal conductivity.

6. Lapping or grinding

If required, the sintered silicon carbide parts can then be machined to precise tolerances using a very costly range of precision diamond grinding or lapping techniques.

7. Quality checks

The finished silicon carbide parts go through a series of dimensional checks, tests and inspections (leak detection, crack detection, pressure testing, etc…). Mechanical properties are carefully checked and monitored after each production batch.

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com