Properties

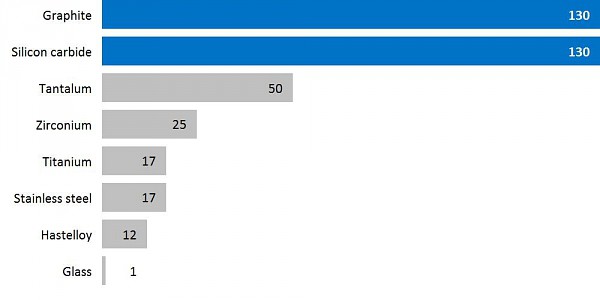

Thermal conductivity in international units (W/m.K)

With thermal conductivity of between 120 and 150 W/m.K, impervious graphite outperforms most materials used for constructing corrosion-resistant process equipment.

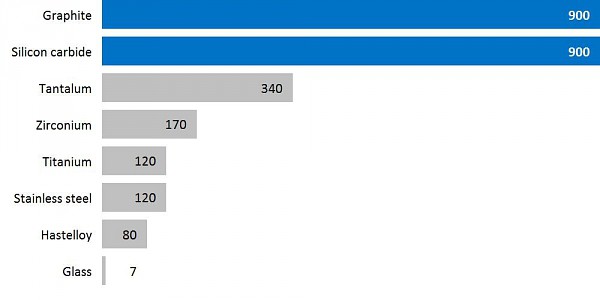

Thermal conductivity in imperial units (BTU.inch/hr.ft2.°F)

With thermal conductivity of between 830 and 1040 BTU.inch/hr.ft2.°F, impervious graphite outperforms most materials used for constructing corrosion-resistant process equipment.

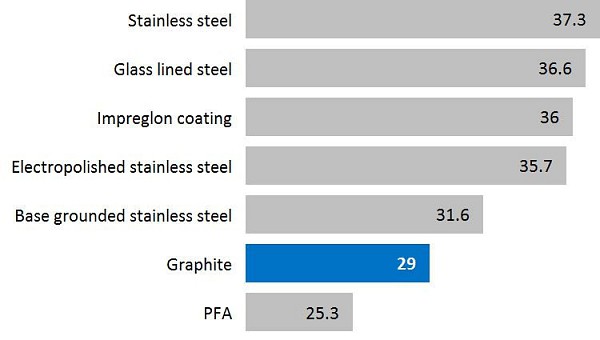

Adhesion angle in degrees (°)

Impervious graphite has a very low adhesion angle compared to most materials of construction used in corrosive applications. This translates into a very low tendency to foul and a great cleanability. This makes graphite a perfect material of construction for condensers above glass-lined reactors in multipurpose plants.

GPX 1, GPX 1T, and GPX 2 impervious graphite grades

GAB Neumann has developed 3 impervious graphite grades, namely our GPX 1, GPX 1T, and GPX 2.

Our GPX 1 is a homogenous, fine grain graphite impregnated with high viscosity phenolic resin and is suitable for most applications. It has a maximum design temperature of 180°C (356°F).

Our GPX 1T is a homogenous, fine grain graphite impregnated with high viscosity phenolic resin and is recommended for most applications above 160°C. It has a maximum design temperature of 200°C (392°F).

Our GPX 2 is a homogenous, fine grain graphite impregnated with high viscosity phenolic resin and is recommended for the most aggressive applications. It has a maximum design temperature of 200°C (392°F).

Raw graphite and impervious graphite properties in international units

|

Grades |

Unit |

GPX 1 |

GPX 1T |

GPX 2 |

|

|

Raw graphite |

Apparent density |

g/cm3 |

1.67 to 1.73 |

1.67 to 1.73 |

1.77 to 1.79 |

|

Open porosities |

% |

about 20 |

about 20 |

about 15 |

|

|

Average grain size |

mm |

0.4 |

0.4 |

0.4 |

|

|

Maximum grain size |

mm |

0.8 |

0.8 |

0.8 |

|

|

Resistivity |

μOhm.m |

10 |

10 |

8 |

|

|

Dynamic modulus of elasticity |

GPa |

6 to 7 |

6 to 7 |

6 to 7 |

|

|

Flexural strength |

MPa |

9 to 10 |

9 to 10 |

16 to 18 |

|

|

Compressive strength |

MPa |

23 to 25 |

23 to 25 |

39 to 41 |

|

|

Tensile strength |

MPa |

6 |

6 |

6 |

|

|

Thermal expansion |

10-6 K-1 |

2 to 3 |

2 to 3 |

2 to 3 |

|

|

Ash content |

% |

≤ 0.07 |

≤ 0.07 |

≤ 0.07 |

|

|

Impregnated graphite |

Apparent density |

g/cm3 |

1.88 to 1.92 |

1.88 to 1.92 |

1.88 to 1.92 |

|

Open porosities |

% |

0 |

0 |

0 |

|

|

Thermal conductivity |

W/m.K |

≥ 120 |

≥ 120 |

≥ 150 |

|

|

Tensile strength |

MPa |

≥ 18 |

≥ 18 |

≥ 20 |

|

|

Maximum design temperature |

°C |

180 |

200 |

200 |

|

Raw graphite and impervious graphite properties in imperial units

|

Grades |

Unit |

GPX 1 |

GPX 1T |

GPX 2 |

|

|

Raw graphite |

Apparent density |

lb/in3 |

0.060 to 0.063 |

0.060 to 0.063 |

0.064 to 0.065 |

|

Open porosities |

% |

about 20 |

about 20 |

about 15 |

|

|

Average grain size |

mils |

15 |

15 |

15 |

|

|

Maximum grain size |

mils |

31.5 |

31.5 |

31.5 |

|

|

Resistivity |

μOhm.in |

394 |

394 |

315 |

|

|

Dynamic modulus of elasticity |

103.Psi |

870 to 1015 |

870 to 1015 |

870 to 1015 |

|

|

Flexural strength |

103.Psi |

1305 to 1450 |

1305 to 1450 |

2320 to 2610 |

|

|

Compressive strength |

103.Psi |

3335 to 3625 |

3335 to 3625 |

5650 to 5945 |

|

|

Tensile strength |

103.Psi |

870 |

870 |

870 |

|

|

Thermal expansion |

10-6.°F-1 |

1.1 to 1.6 |

1.1 to 1.6 |

1.1 to 1.6 |

|

|

Ash content |

% |

≤ 0.07 |

≤ 0.07 |

≤ 0.07 |

|

|

Impregnated graphite |

Apparent density |

lb/in3 |

0.068 to 0.069 |

0.068 to 0.069 |

0.068 to 0.069 |

|

Open porosities |

% |

0 |

0 |

0 |

|

|

Thermal conductivity |

BTU.inch/hr.ft2.°F |

≥ 830 |

≥ 830 |

≥ 1040 |

|

|

Tensile strength |

103.Psi |

≥ 2.6 |

≥ 2.6 |

≥ 2.9 |

|

|

Maximum design temperature |

°F |

356 |

392 |

392 |

|

|

|

|||||

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com