Silicon carbide shell and tube heat exchangers

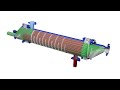

CORRESIC® Silicon carbide shell and tube heat exchangers are adapted to the cooling, condensation, heating, evaporation and absorption of highly corrosive chemicals. Silicon carbide shell and tube heat exchangers consist in a bundle of silicon carbide tubes inside a shell. One fluid runs through the tubes and another fluid flows over the tubes (through the shell). The heat is transferred by conduction through the silicon carbide tube wall, without direct contact between the fluids.

Snapshots

PFA lined tube sheet of a SiC shell and tube heat exchanger

The CORRESIC® compact sealing system with double O-ring gasket and triple tube sheet ensures a maximum operational safety

SiC tubes before assembly in a shell and tube heat exchanger

GAB Neumann only uses pressure less sintered silicon carbide tubes for their upmost corrosion resistance against acids, alkalis and oxidizing media.

SiC heat exchanger with a glass shell

GAB Neumann offers a wide range of materials of construction for the headers and the shell including glass, glass lined steel, PTFE lined steel, carbon steel and stainless steel.

Baffle cage in solid anti-static fiber reinforced PTFE

GAB Neumann offers a wide range of materials of construction for the baffles including stainless steel and PTFE.

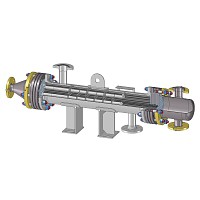

3D Renderings

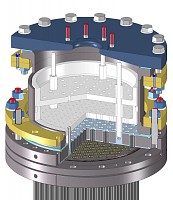

SiC shell and tube heat exchanger with glass lined headers and carbon steel shell

GAB Neumann’s silicon carbide shell and tube heat exchangers’ headers and shell can be in glass lined steel, carbon steel, stainless steel, glass, PTFE lined steel depending on the process requirements

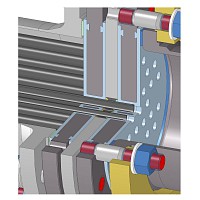

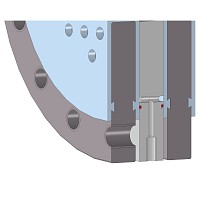

Details of GAB Neumann’s unique triple tube sheet double O’ring sealing system

GAB Neumann’s silicon carbide shell and tube heat exchangers’ unique sealing system associates two PFA lined tube sheets, a stainless steel intermediate tube sheets as well as two O’ring gaskets at each end of each single tube. It is the safest and most reliable tube to tube sheet sealing system in the industry

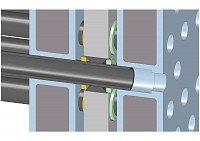

Details of a GAB Neumann’s unique sealing system

Our SiC heat exchangers are fitted with GAB Neumann’s unique and upmost reliable triple tube sheet double O’ring gasket sealing system (here before tightening) that guaranties the performance of the equipment on the long term.

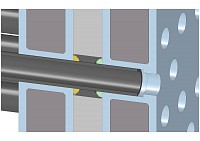

Details of a GAB Neumann’s unique sealing system

Our SiC heat exchangers are fitted with GAB Neumann’s unique and upmost reliable triple tube sheet double O’ring gasket sealing system (here after tightening) that guaranties the performance of the equipment on the long term.

Details of GAB Neumann’s unique leak detection system

GAB Neumann’s leak detection system would inform the user in case of any process or service side gasket failure and this before any cross-contamination occurs.

Details of a GAB Neumann’s silicon carbide falling film evaporator

GAB Neumann’s silicon carbide shell and tube falling film evaporator includes a sophisticated two stages liquid distribution system.

3D animations

Materials:

- CORRESIC® pressureless sintered silicon carbide tubes

- PFA lined tube sheets

- FFKM O’ring gaskets on process side

- FKM or FFKM O’ring gaskets on service side

- Headers in Glass lined steel, PTFE lined steel, glass, carbon steel, or stainless steel

- Shell in in Carbon steel, stainless steel, glass lined steel, PTFE lined steel or glass

- Tie rods, nuts, bolts, washers: stainless steel

Design:

- Universally corrosion resistant silicon carbide (SiC) tubes

- PFA lined tube sheets

- Unique sealing system with FFKM and FKM O’ring gaskets

- Outstanding thermal conductivity

- Adjustable number of tubes, size, length, and number of passes on both sides

- Shell diameter from 100 to 400 mm

- 14, 19 or 25 mm Ø tubes

- 1000 mm to 4500 mm long tubes

- Glass lined steel, PTFE lined steel, or glass for the shell or headers on process side

- Carbon steel, stainless steel, glass lined steel, PTFE lined steel, or glass for the shell or headers on service side

- Unique, ultra-safe and reliable triple tube sheet / double sealing system

Key Features:

- Design pressure: -1 barg (full vacuum) to +10 barg

- Design temperature: -30 to +220°C (-22 to 428°F)

- Heat transfer area: 0,4 to 42 m2 (4 to 452 ft2)

- Design: according to European Pressure Equipment Directive 2014/68/EU (PED) or ASME Code

Key Benefits:

- Universal corrosion resistance against acids, alkalis and oxidizing media

- Ultra-corrosive media either in or outside the tubes

- Possibility to have ultra-corrosive media on both sides.

- Superior heat transfer performance thanks to adjustable cross sections on both sides that guaranty a high level of turbulence

- High operational safety

- Highly reliable equipment therefore low cost of ownership and low maintenance cost

- Extreme purity of silicon carbide

- Wide range of materials of construction for the shell and the headers

- Compact and robust design

- Short lead time

- Long lifetime

Optional features:

- Sight glass

- Cleaning in place

- Twisted tapes for performance enhancement

Main applications:

- Condensation of ultra-corrosive and oxidizing vapors in multipurpose units

- Cooling or heating of ultra-corrosive and oxidizing liquids

- Suited for multi and single purpose units

Technical documentation

Shell and tube heat exchangers

Their modular and versatile design allows very efficient heat transfer thanks to adjustable cross sections on both sides that guaranty a high level of turbulence.

The thermal performance of shell and tube heat exchangers can vary significantly. It is therefore essential to select the type and size of shell and tube heat exchangers (tube count, tube diameter, tube length, pitch, baffle count, opening) that is the most adapted to the specific application and industrial process. There are a number of considerations including flow rate, pressure drop, design pressure and temperature, materials compatibility, fouling, and many more that should be taken in account.

GAB Neumann’s silicon carbide shell and tube heat exchangers SR series

GAB Neumann’s silicon carbide shell and tube heat exchangers are designed to condense, cool down, heat up, evaporate or absorb ultra-corrosive and/or oxidizing fluids. Safety, reliability, and performance on the long-term are our primary considerations when we size, design and manufacture SiC shell and tube heat exchangers.

Our extended and highly customizable silicon carbide shell and tube heat exchangers portfolio enables us to provide particularly adapted solutions to the most complex heat transfer challenges. All our SiC shell and tube heat exchangers designs are totally modular to best fit with individual process specification. The number, length and diameter of tubes as well as the number of passes both on process and service sides can be adapted to best meet the velocities, pressure drops, and heat transfer requirements.

On request, they can be fitted with optional features such as sight glasses and cleaning in place.

Our SiC shell and tube heat exchangers are all fitted with GAB Neumann’s unique and upmost reliable triple tube sheet double O’ring gasket sealing system that guaranties the performance of the equipment on the long term.

Industrial processes:

- Crop protection

- Explosives

- Fine chemicals

- Active pharmaceutical ingredients

- Stainless-steel pickling

- Fire retardants

- Flavors and fragrances

- Vitamins

- Polycarbonate

- Coagulants

- Treatment, purification and concentration of spent acids

- Manufacturing of ultra-pure acids for electronic applications

- and many more…

Associated products

GAB Neumann GmbH

Alemannenstrasse 29

79689 Maulburg

Germany

GAB Neumann GmbH | Alemannenstrasse 29 | D-79689 Maulburg | Phone +49 (7622) 6751 0 | Fax +49 (7622) 6751 20 | E-Mail info@gab-neumann.de | www.gab-neumann.com